Introducción

La serie ZKS de transportadores neumáticos por vacío ofrece un manejo de polvo seguro e higiénico. Se utilizan en todas las industrias farmacéutica, alimentaria y química para la transferencia de polvo, polvo, material granulado y componentes pequeños. Incluso las pequeñas virutas de metal del fresado se pueden aspirar y transportar sin causar desgaste al transportador.

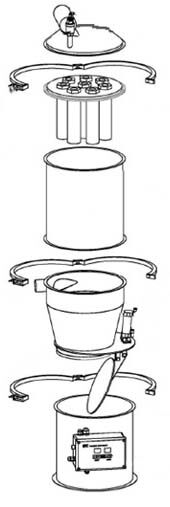

El transportador de vacío consta de una bomba de vacío (sin aceite ni agua), tubo de succión de acero inoxidable, manguera flexible, filtro de PE o filtro SUS 316, dispositivo de limpieza de aire comprimido, dispositivo de descarga neumático, tolva de vacío y dispositivo de control de nivel automático.

El alimentador de vacío se divide en dos tipos: descarga por espacio y descarga continua. La descarga de la brecha ayuda a reducir el costo de inversión del equipo y facilita el control del nivel de material. En la mayoría de los casos, recomendamos que el usuario utilice el tipo de descarga por espacio. La descarga continua se utiliza generalmente para el transporte por vacío de materiales a largas distancias y grandes volúmenes de producción.

Especificaciones

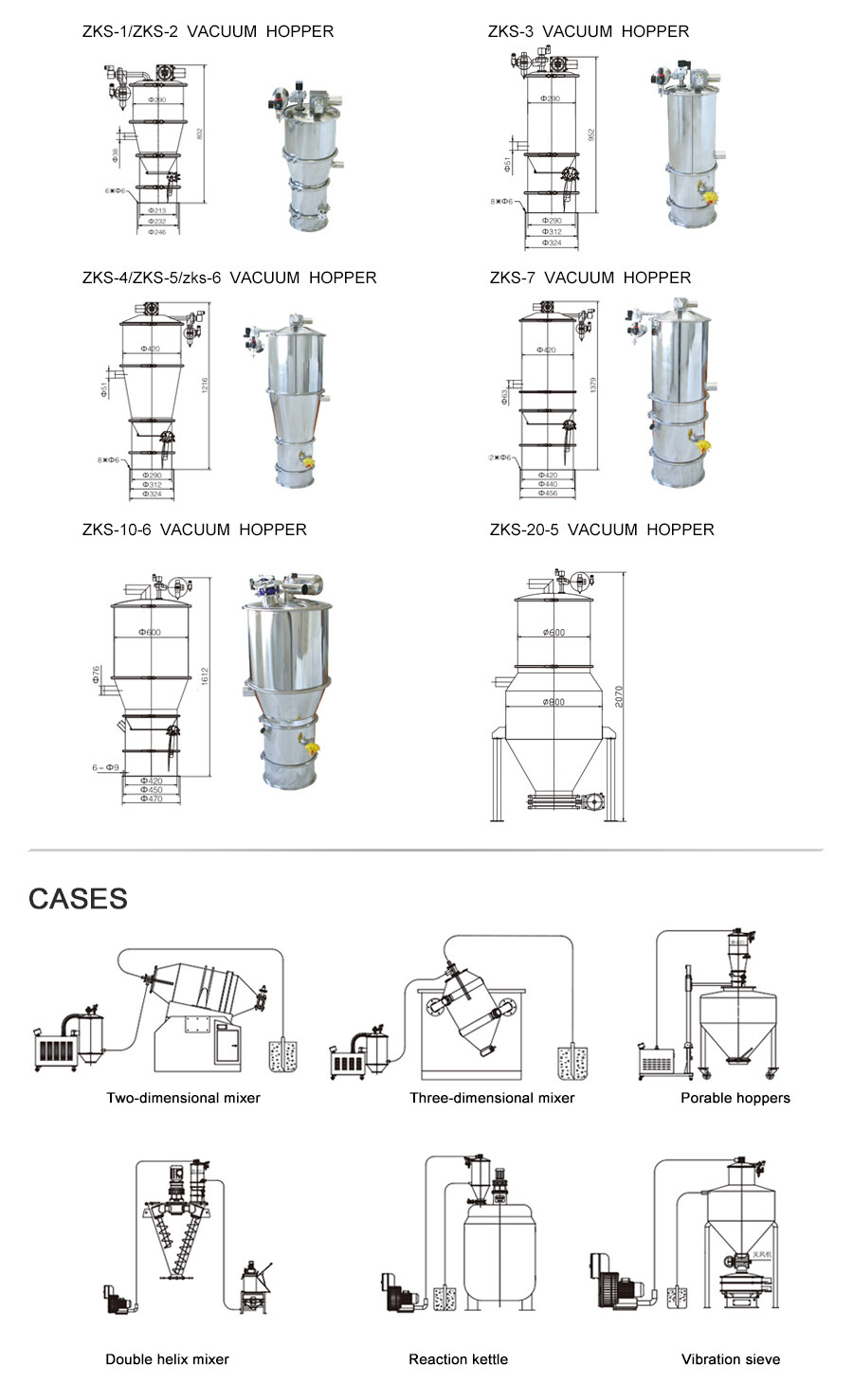

| Modelo | Capacidad | Potencia | Aire comprimido | Presión del aire | Tamaño(mm) |

|---|---|---|---|---|---|

| ZKS-1 | 400L/h | 1.5kw | 8L/min | 0.5-0.6Mpa | Φ290*802 |

| ZKS-2 | 600L/h | 2.2kw | 8L/min | 0.5-0.6Mpa | Φ290*802 |

| ZKS-3 | 1200L/h | 3kw | 10L/min | 0.5-0.6Mpa | Φ290*952 |

| ZKS-4 | 2000L/h | 5.5kw | 12L/min | 0.5-0.6Mpa | Φ420*1216 |

| ZKS-5 | 3000L/h | 4kw | 12L/min | 0.5-0.6Mpa | Φ420*1216 |

| ZKS-6 | 4000L/h | 5.5kw | 12L/min | 0.5-0.6Mpa | Φ420*1216 |

| ZKS-7 | 6000L/h | 7.5kw | 17L/min | 0.5-0.6Mpa | Φ420*1379 |

| ZKS-10-6 | 6000L/h(Conveying distance 10m) | 7.5kw | 34L/min | 0.5-0.6Mpa | Φ600*1612 |

| ZKS-20-5 | 5000L/h (Conveying distance 20m) | 11kw | 68L/min | 0.5-0.6Mpa | Φ800*2070 |

Nota: La capacidad de transporte se mide cuando el tubo de transporte tiene 4 metros de largo y el material de transporte es harina. Cuanto más largo sea el tubo de transporte, menor será la capacidad de transporte. La capacidad de transporte también tiene una relación significativa con las propiedades de los materiales.

Observaciones

- Transporte al vacío: seguro, fácil y eficiente

- HIGIENE: Evite la dispersión de polvo y la contaminación del producto. El material transportado se mantiene en un entorno aislado desde la recogida hasta el punto de liberación.

- CALIDAD DEL PRODUCTO: Mueva las mezclas farmacéuticas conservando su integridad y manteniendo intactos los porcentajes de componentes individuales.

- PRODUCTIVIDAD: Aumente la automatización y la salud y seguridad de su personal al eliminar la tarea de introducir manualmente el polvo en las máquinas de proceso. El transporte puede reducir los requisitos de personal y los tiempos de carga en más del 50%.

Estructura

Principio de funcionamiento

Cuando la bomba de aire gira, la presión negativa de la bomba de aire forma un flujo de aire de vacío y el material es succionado hacia el puerto de succión para formar un flujo de gas, que pasa a través del tubo de succión y llega al silo de la máquina de carga. El filtro separa completamente el material del aire. Cuando el material se llena en el silo, el controlador corta automáticamente la energía, el alimentador de vacío deja de funcionar y la puerta del silo se abre automáticamente y el material cae en la tolva del equipo. Al mismo tiempo, el aire comprimido limpia automáticamente el filtro a través de una válvula de retrolavado de pulsos. El alimentador se pone en marcha automáticamente cuando se acaba el tiempo o el sensor de nivel envía una señal de carga. El modelo de utilidad tiene las ventajas de estructura simple, pequeño volumen, sin mantenimiento, bajo nivel de ruido, control conveniente, eliminación de la electricidad estática de los materiales y cumplimiento de los requisitos. El alto vacío generado por la bomba de aire de vacío, el alimentador de polvo de vacío de la bomba de aire utiliza la alta presión de la bomba de aire para realizar el transporte del material. Se evita la estratificación del material a transportar y se asegura la uniformidad de la composición de la mezcla. Es la primera opción para la alimentación automática mecánica de maquinaria no tejida, prensa de tabletas, máquina llenadora de cápsulas, granuladora en seco, máquina envasadora, pulverizadora y criba vibratoria.

Factores que afectan la precisión del alimentador por vacío

Métodos de posicionamiento

Los diferentes métodos de posicionamiento tienen diferentes factores de influencia. Cuando se posiciona el tope mecánico, la precisión de posicionamiento está relacionada con la rigidez del bloque y la velocidad a la que se apoya el bloque.

Velocidad de posicionamiento

La velocidad de posicionamiento tiene una gran influencia en la precisión del posicionamiento. Esto se debe a que la energía de las partes móviles que deben disiparse difiere cuando la velocidad de posicionamiento es diferente. Generalmente, para reducir el error de posicionamiento, la velocidad de posicionamiento debe controlarse razonablemente, como mejorar el rendimiento de amortiguación y la eficiencia de amortiguación del dispositivo amortiguador, y controlar el sistema de conducción para ralentizar las partes móviles a tiempo.

Precisión del equipo

La precisión de fabricación del manipulador y la precisión del control de velocidad de instalación tienen un impacto directo en la precisión de posicionamiento.

Peso de las partes móviles

El peso de la parte móvil incluye el peso del propio robot y el peso del objeto a agarrar. El cambio en el peso de las partes móviles tiene una gran influencia en la precisión del posicionamiento. Generalmente, cuando se aumenta el peso del miembro móvil, se reduce la precisión de posicionamiento. Por lo tanto, no solo es necesario reducir el peso de las partes móviles, sino también considerar la influencia del cambio en el peso durante el trabajo.

Precisión del control de posición

La precisión del control de posición del control del interruptor del sistema de control, el control proporcional electrohidráulico y el servocontrol es diferente. Esto no solo se debe a la diferente precisión y sensibilidad de los diversos elementos de control, sino también a la presencia o ausencia de dispositivos de retroalimentación de posición.

revisión (s)

Best

The vacuum delivery is very good, and the capsules are safe and sound.

From: Chius | Fecha: 03/03/2021 21:33

Escriba su propia opinión

También Ofrece

Productos relacionados

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche